Essential Insights into the Key Properties of ASTM A403 Stainless Steel Tee

2025-08-04

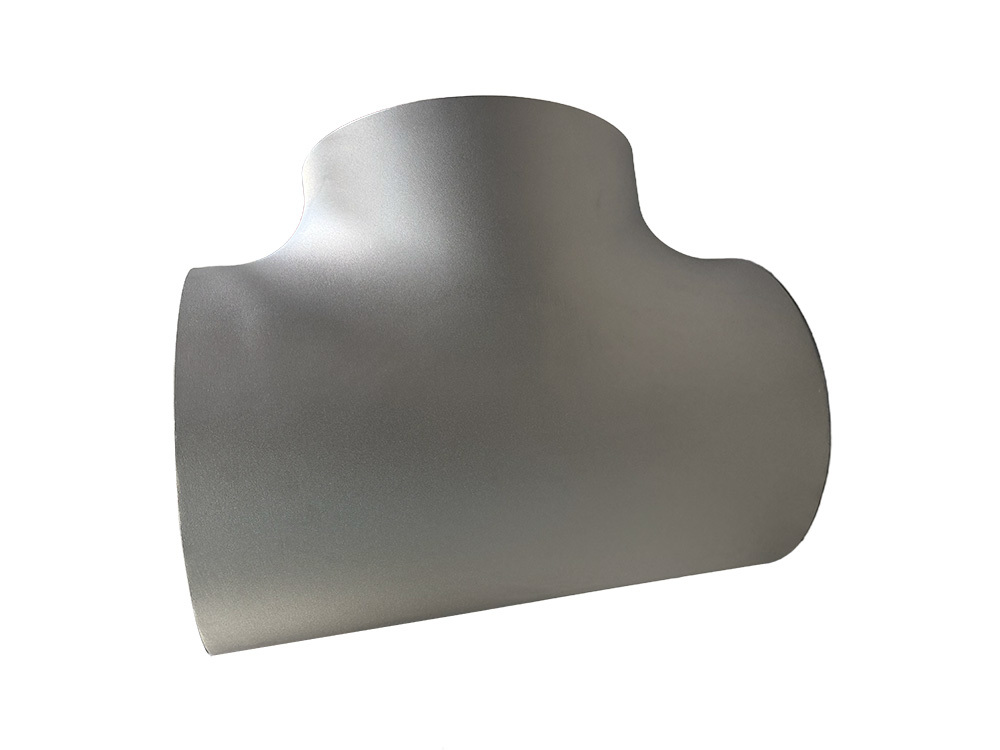

Key Properties of ASTM A403 Stainless Steel Tee You Should Know

Understanding ASTM A403 Stainless Steel Tee

When it comes to reliable piping systems, the materials we choose play a critical role in ensuring durability and efficiency. Among these materials, the ASTM A403 stainless steel tee stands out as an essential component. This article delves into the key properties of ASTM A403 stainless steel tees, helping professionals and enthusiasts alike understand why these fittings are indispensable in plumbing and construction.

What is ASTM A403 Stainless Steel?

ASTM A403 is a specification developed by the American Society for Testing and Materials (ASTM) outlining the standards for wrought austenitic stainless steel fittings. These fittings are designed for pressure piping and are crucial in various industries, including petrochemical, oil and gas, and water treatment. The designation "A403" signifies that the product meets stringent quality and performance criteria, ensuring reliability in demanding applications.

Types of Stainless Steel Used in ASTM A403

The ASTM A403 specification covers several grades of stainless steel, each with unique properties that make them suitable for different environments. The most common grades include:

- Type 304: Known for its excellent corrosion resistance, Type 304 is widely used in a variety of applications.

- Type 316: This grade offers enhanced corrosion resistance, particularly against chlorides, making it ideal for marine environments.

- Type 321: Featuring good high-temperature strength, Type 321 is often used in applications involving elevated temperatures.

Key Properties of ASTM A403 Stainless Steel Tees

1. **Corrosion Resistance**

One of the standout features of ASTM A403 stainless steel is its exceptional resistance to corrosion. This property is particularly important in environments where exposure to moisture, chemicals, and other corrosive elements is prevalent. The chromium content in stainless steel forms a passive layer of chromium oxide on the surface, which acts as a barrier, protecting the underlying metal from corrosive substances.

2. **Mechanical Strength and Durability**

ASTM A403 stainless steel tees are engineered to withstand high pressure and stress. Their mechanical properties, including yield strength and tensile strength, are crucial for ensuring the integrity of piping systems. These fittings can endure extreme conditions, making them suitable for applications ranging from residential plumbing to high-pressure industrial systems.

Comparative Strength of ASTM A403 Grades

Different grades of ASTM A403 stainless steel offer varying levels of mechanical strength:

- Type 304: Yield strength of approximately 205 MPa (30,000 psi)

- Type 316: Yield strength of around 290 MPa (42,000 psi)

- Type 321: High-temperature applications with yield strength exceeding 310 MPa (45,000 psi)

3. **Weldability**

The ability to weld stainless steel tees without compromising their integrity is a significant advantage. ASTM A403 fittings are designed to be easily welded, allowing for seamless integration into piping systems. Proper welding techniques ensure that the corrosion resistance and mechanical properties are maintained in the welded areas, providing reliability throughout the system.

4. **Temperature Resistance**

ASTM A403 stainless steel tees are suitable for applications involving fluctuating temperatures. The austenitic structure of these steels provides excellent toughness at low temperatures while maintaining strength at high temperatures. This property is particularly beneficial in applications where thermal expansion and contraction are concerns.

5. **Versatility in Applications**

Due to their robust properties, ASTM A403 stainless steel tees are versatile fittings used across various industries. Common applications include:

- **Chemical Processing:** Handling corrosive substances without risk of degradation.

- **Oil and Gas:** Ensuring reliability in high-pressure and high-temperature environments.

- **Food and Beverage:** Meeting hygiene standards while providing durability.

Choosing the Right ASTM A403 Stainless Steel Tee

Factors to Consider

When selecting ASTM A403 stainless steel tees for your projects, several factors should be taken into account:

- Application Requirements: Consider the specific requirements of your application, including pressure ratings and temperature ranges.

- Compatibility: Ensure compatibility with other materials in the piping system to avoid galvanic corrosion.

- Regulations and Standards: Adhere to local and industry standards that dictate the use of materials in specific applications.

Common Sizes and Configurations

ASTM A403 stainless steel tees come in various sizes and configurations, making it essential to choose the right fit for your system. Common sizes range from ½ inch to 12 inches, with options for both straight and reducing tees. Understanding the flow requirements and space constraints will guide your selection process.

Installation Best Practices

Preparing for Installation

Proper installation of ASTM A403 stainless steel tees is crucial for ensuring system integrity. Here are some best practices to consider:

- Cleanliness: Ensure all surfaces are clean and free from contaminants before installation.

- Alignment: Carefully align the fittings to prevent stress points that could lead to failure.

- Use of Proper Tools: Utilize appropriate tools and techniques to avoid damaging the fittings during installation.

Post-Installation Checks

After installation, conduct thorough checks to ensure everything is secure. Look for any leaks and verify that the fittings have been correctly installed. Regular maintenance and inspections are vital for preserving the longevity and performance of the piping system.

FAQs About ASTM A403 Stainless Steel Tees

1. What is the difference between ASTM A403 and other stainless steel specifications?

ASTM A403 specifically focuses on wrought stainless steel fittings used in pressure piping, whereas other specifications may cover different forms or types of stainless steel products.

2. Can ASTM A403 stainless steel tees be used in high-temperature applications?

Yes, certain grades such as Type 321 are designed for high-temperature applications, providing excellent performance under such conditions.

3. Are ASTM A403 fittings resistant to pitting corrosion?

Yes, particularly Type 316 stainless steel, which offers enhanced resistance to pitting corrosion in chloride environments.

4. How do I choose the right size of ASTM A403 stainless steel tee?

Consider the flow requirements, system dimensions, and compatibility with existing piping to select the appropriate size for your application.

5. What maintenance is required for ASTM A403 stainless steel tees?

Regular inspections for signs of corrosion, leaks, and mechanical stress are recommended to maintain the integrity of the fittings over time.

Conclusion

Understanding the key properties of ASTM A403 stainless steel tees is essential for anyone involved in construction, plumbing, or industrial applications. From their remarkable corrosion resistance and mechanical strength to their versatility in various environments, these fittings provide unmatched reliability. By considering the properties outlined in this article and adhering to best practices in installation and maintenance, you can ensure that your piping systems remain safe and efficient for years to come.

Blog

Key Features That Make 304L Stainless Steel Elbow a Preferred Choice in Construction and Decoration