Maximizing Longevity: The Importance of 3PE Coating for Steel Pipes

2025-08-20

Maximizing Longevity: The Importance of 3PE Coating for Steel Pipes

Table of Contents

- Introduction to 3PE Coating and Steel Pipes

- What is 3PE Coating?

- Benefits of Using 3PE Coating for Steel Pipes

- Applications of 3PE Coated Steel Pipes

- Maintenance and Care of 3PE Coated Steel Pipes

- Challenges and Limitations of 3PE Coating

- The Future of 3PE Coating Technology

- Frequently Asked Questions

- Conclusion

Introduction to 3PE Coating and Steel Pipes

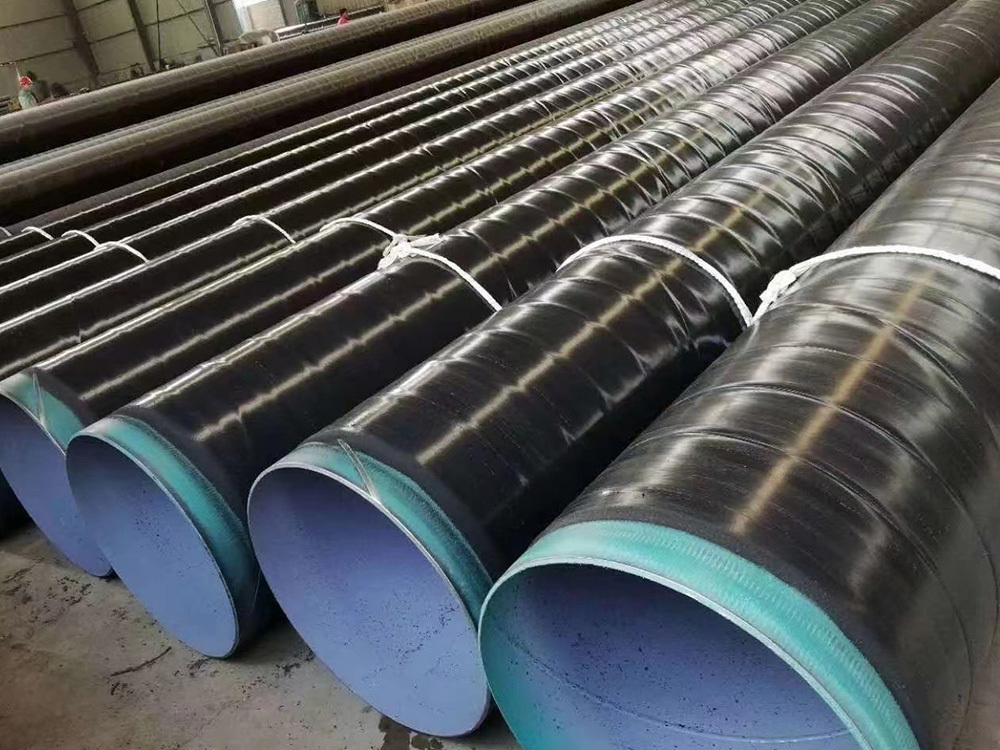

In the construction and infrastructure industries, the durability of materials is paramount. When it comes to **steel pipes**, their longevity can significantly impact the overall integrity of a structure. Traditional methods of protecting steel pipes from corrosion often fall short, leading to costly repairs and replacements. That's where **3PE (Three-Layer Polyethylene)** coating comes into play. This innovative coating technology has revolutionized the protection of steel pipes, ensuring they endure harsh environmental conditions while maintaining their structural integrity. In this article, we delve into the importance of 3PE coating and how it maximizes the longevity of steel pipes.

What is 3PE Coating?

3PE coating is an advanced method of protecting steel pipes designed to prevent corrosion and deterioration over time. This three-layer system consists of:

Components of 3PE Coating

1. **Epoxy Primer**: The first layer is an epoxy primer that provides excellent adhesion to the steel surface while offering resistance to corrosion.

2. **Polyethylene Adhesive Layer**: The second layer, which acts as an adhesive, bonds the epoxy to the final layer, ensuring that the coating adheres securely to the steel.

3. **Polyethylene Outer Layer**: The third and final layer is a high-density polyethylene (HDPE) layer that provides robust protection against physical damage, moisture, and chemical exposure.

This multi-layered approach ensures that the steel pipe is well-protected from various environmental factors that can lead to premature wear and corrosion.

Application Process of 3PE Coating

The application of 3PE coating involves several meticulous steps to ensure the highest quality protection for steel pipes:

- **Surface Preparation**: The steel pipes are cleaned and prepared to remove any rust, dirt, or contaminants. This step is crucial for ensuring proper adhesion of the coating.

- **Priming**: An epoxy primer is applied to the clean surface, allowing it to cure before the next layer is added.

- **Applying the Adhesive Layer**: Once the primer has cured, the polyethylene adhesive layer is applied. This layer not only adheres the polyethylene to the epoxy but also enhances the overall durability of the coating.

- **Adding the Outer Layer**: The final layer of HDPE is applied, creating a protective barrier against environmental factors.

- **Curing**: The entire assembly is allowed to cure, completing the coating process.

This detailed approach ensures that the 3PE coating adheres effectively to the steel pipe, providing long-lasting protection.

Benefits of Using 3PE Coating for Steel Pipes

The adoption of 3PE coating offers numerous advantages that can significantly enhance the performance and longevity of steel pipes. Some of the most notable benefits include:

Corrosion Resistance

One of the primary advantages of 3PE coating is its exceptional corrosion resistance. The combination of the epoxy primer and the HDPE outer layer creates a formidable barrier against moisture and corrosive substances. This makes 3PE-coated steel pipes ideal for use in environments prone to corrosion, such as coastal areas or industrial settings.

Extended Lifespan

By effectively preventing corrosion, 3PE coating significantly extends the lifespan of steel pipes. While uncoated pipes may only last a few years before requiring replacement, 3PE-coated pipes can endure for decades, reducing the need for frequent repairs and replacements. This longevity translates to lower maintenance costs and improved efficiency for construction projects.

Cost Effectiveness

Although the initial investment in 3PE coating might be higher than traditional protective methods, the long-term savings are substantial. The reduced frequency of repairs, replacements, and maintenance can lead to significant cost savings over time. Additionally, the durability of 3PE-coated pipes means fewer disruptions to projects, enhancing overall productivity.

Applications of 3PE Coated Steel Pipes

3PE-coated steel pipes are utilized across various industries due to their remarkable properties. Some common applications include:

- **Oil and Gas Pipelines**: The oil and gas sector benefits greatly from the corrosion resistance of 3PE-coated pipes, ensuring safe and efficient transport of these valuable resources.

- **Water Supply Systems**: Municipal water supply systems frequently use 3PE-coated steel pipes to prevent corrosion, ensuring safe and clean drinking water for communities.

- **Construction and Infrastructure**: In construction projects, 3PE-coated pipes are used for structural applications where durability is essential.

These applications highlight the versatility and effectiveness of 3PE-coated steel pipes in diverse environments.

Maintenance and Care of 3PE Coated Steel Pipes

While 3PE coating provides robust protection, regular maintenance is still essential to ensure optimal performance. Here are some tips for maintaining 3PE-coated steel pipes:

- **Regular Inspections**: Periodically inspect pipes for any signs of damage or wear. Early detection can prevent more significant issues.

- **Cleaning**: Keep the outer surface clean to prevent the accumulation of dirt and debris, which can lead to deterioration over time.

- **Handling and Transportation**: When transporting or handling pipes, take care to avoid impacts that could damage the coating.

By following these maintenance tips, the longevity and effectiveness of 3PE-coated steel pipes can be maximized.

Challenges and Limitations of 3PE Coating

Despite its numerous benefits, 3PE coating does have some challenges and limitations:

- **Initial Cost**: The upfront cost of 3PE coating may deter some companies from adopting this technology, even though long-term savings are significant.

- **Application Complexity**: The application process requires specialized equipment and skilled personnel, which can complicate implementation.

- **Environmental Factors**: In extreme conditions, such as high temperatures or heavy mechanical stress, the performance of the coating may be affected.

Understanding these challenges can help companies make informed decisions regarding the use of 3PE coating.

The Future of 3PE Coating Technology

The future looks promising for 3PE coating technology, with ongoing research and innovations aimed at enhancing its effectiveness. As industries continue to prioritize sustainability and durability, advancements in coating materials and application methods are expected. Potential developments may include:

- **Eco-Friendly Coatings**: The development of environmentally friendly coating materials is likely to gain traction, aligning with global sustainability goals.

- **Smart Coatings**: Innovative smart coatings that can detect corrosion or environmental changes may enhance monitoring and maintenance efforts.

- **Improved Application Techniques**: Streamlined application processes and enhanced equipment could reduce costs and improve efficiency for manufacturers.

These developments suggest a bright future for 3PE coating, making it an even more attractive option for protecting steel pipes.

Frequently Asked Questions

1. What is the lifespan of 3PE-coated steel pipes?

3PE-coated steel pipes can last for decades, often exceeding 30 years, depending on environmental conditions and maintenance practices.

2. Can 3PE coating be applied to existing steel pipes?

Yes, 3PE coating can be retrofitted onto existing steel pipes, though proper surface preparation and application techniques are essential for optimal adhesion.

3. Is 3PE coating suitable for all environmental conditions?

While 3PE coating is highly effective in various environments, extreme conditions such as excessive heat or mechanical stress may affect its performance.

4. How does 3PE coating compare to other coating methods?

3PE coating offers superior corrosion resistance and longevity compared to many traditional coatings, making it a cost-effective choice in the long run.

5. What maintenance is required for 3PE-coated pipes?

Regular inspections, cleaning, and gentle handling during transport are recommended to maintain the integrity of 3PE-coated pipes.

Conclusion

In conclusion, the significance of **3PE coating for steel pipes** cannot be overstated. This advanced protective technology not only enhances the durability and lifespan of steel pipes but also offers cost-effective benefits that resonate deeply within the construction and infrastructure industries. From its superior corrosion resistance to its versatility in various applications, 3PE coating stands out as a leading solution for preserving the structural integrity of steel pipes. As we continue to innovate and advance in this field, embracing 3PE coating will undoubtedly lead to more sustainable and resilient construction practices. By prioritizing the implementation of this technology, we can maximize the longevity of steel pipes and ensure the success of future projects.

Blog

Key Features That Make 304L Stainless Steel Elbow a Preferred Choice in Construction and Decoration