Enhancing Offshore Operations with 3PE Anti-Corrosion Pipeline Technology

2025-06-05

---

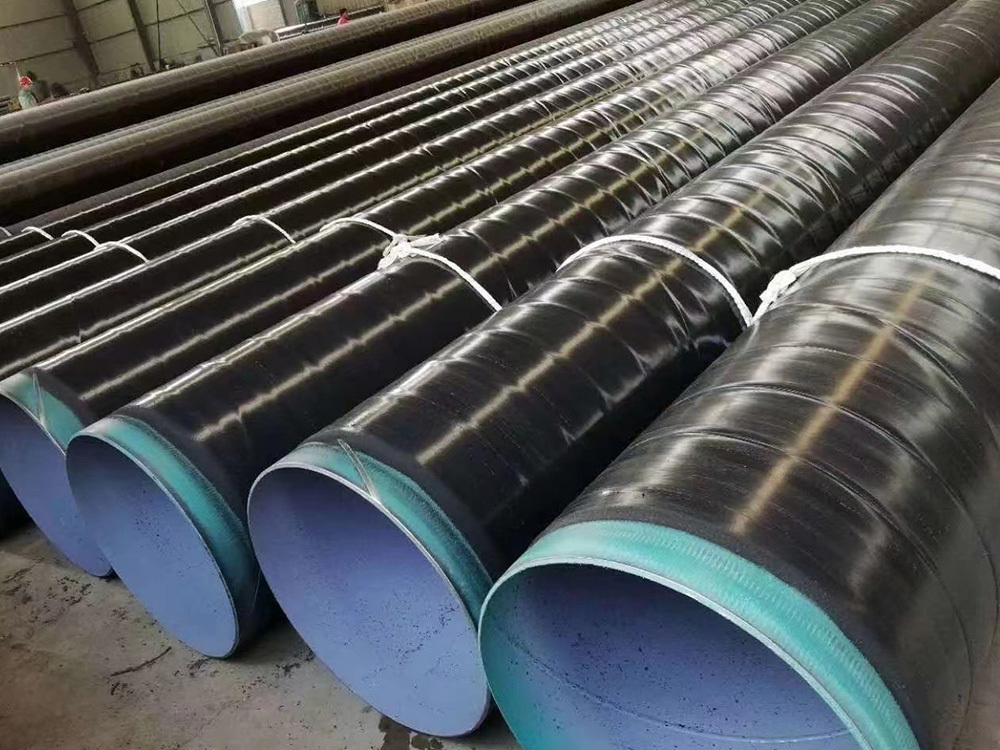

In the industrial pipeline sector, particularly for offshore applications, the integrity and durability of pipelines are of utmost importance. One prominent solution is the 3PE Anti-Corrosion Pipeline, which stands for Three-Layer Polyethylene coating. This technology is engineered to provide exceptional resistance against corrosion, ensuring the longevity of pipelines in harsh marine conditions.

The 3PE coating system comprises three distinct layers: the first layer is a fusion-bonded epoxy (FBE), which serves as a primer to promote adhesion. The second layer involves an adhesive layer that enhances the bond between the FBE layer and the outer polyethylene layer. Finally, the third layer is a polyethylene coating that provides mechanical protection and environmental resistance. This multi-layer approach significantly fortifies the pipeline against corrosive elements found in seawater, such as salts and other chemicals.

One of the key benefits of using 3PE Anti-Corrosion Pipelines in offshore applications is their exceptional resistance to cathodic disbondment. This characteristic is crucial in marine environments where pipelines are often exposed to electrochemical reactions that can lead to premature failure. The robust bonding provided by the 3PE system ensures that the coating remains intact, thus safeguarding the pipeline from corrosion that can compromise its structural integrity.

Additionally, 3PE pipelines are designed to withstand extreme weather conditions, including high humidity and temperature fluctuations, which are common in offshore settings. The flexibility and toughness of the polyethylene layer allow these pipelines to adapt to harsh operational conditions without cracking or degrading, thereby reducing maintenance costs and downtime.

Moreover, the application of 3PE technology contributes to environmental protection. By preventing leaks and minimizing the risk of spills, this pipeline system not only safeguards marine ecosystems but also ensures compliance with strict regulatory standards governing offshore operations. The effective implementation of 3PE anti-corrosion pipelines thus plays a significant role in promoting sustainable industrial practices.

In summary, the adoption of 3PE Anti-Corrosion Pipeline technology in offshore applications is a strategic move towards enhancing operational efficiency and environmental responsibility. By providing exceptional protection against corrosion and mechanical damage, these pipelines ensure that industrial operations can proceed smoothly and sustainably, even in the most challenging maritime environments. For professionals in the industrial equipment and pipeline sector, understanding the advantages of 3PE technology is essential for making informed decisions that can lead to improved performance and reliability in offshore projects.

In the industrial pipeline sector, particularly for offshore applications, the integrity and durability of pipelines are of utmost importance. One prominent solution is the 3PE Anti-Corrosion Pipeline, which stands for Three-Layer Polyethylene coating. This technology is engineered to provide exceptional resistance against corrosion, ensuring the longevity of pipelines in harsh marine conditions.

The 3PE coating system comprises three distinct layers: the first layer is a fusion-bonded epoxy (FBE), which serves as a primer to promote adhesion. The second layer involves an adhesive layer that enhances the bond between the FBE layer and the outer polyethylene layer. Finally, the third layer is a polyethylene coating that provides mechanical protection and environmental resistance. This multi-layer approach significantly fortifies the pipeline against corrosive elements found in seawater, such as salts and other chemicals.

One of the key benefits of using 3PE Anti-Corrosion Pipelines in offshore applications is their exceptional resistance to cathodic disbondment. This characteristic is crucial in marine environments where pipelines are often exposed to electrochemical reactions that can lead to premature failure. The robust bonding provided by the 3PE system ensures that the coating remains intact, thus safeguarding the pipeline from corrosion that can compromise its structural integrity.

Additionally, 3PE pipelines are designed to withstand extreme weather conditions, including high humidity and temperature fluctuations, which are common in offshore settings. The flexibility and toughness of the polyethylene layer allow these pipelines to adapt to harsh operational conditions without cracking or degrading, thereby reducing maintenance costs and downtime.

Moreover, the application of 3PE technology contributes to environmental protection. By preventing leaks and minimizing the risk of spills, this pipeline system not only safeguards marine ecosystems but also ensures compliance with strict regulatory standards governing offshore operations. The effective implementation of 3PE anti-corrosion pipelines thus plays a significant role in promoting sustainable industrial practices.

In summary, the adoption of 3PE Anti-Corrosion Pipeline technology in offshore applications is a strategic move towards enhancing operational efficiency and environmental responsibility. By providing exceptional protection against corrosion and mechanical damage, these pipelines ensure that industrial operations can proceed smoothly and sustainably, even in the most challenging maritime environments. For professionals in the industrial equipment and pipeline sector, understanding the advantages of 3PE technology is essential for making informed decisions that can lead to improved performance and reliability in offshore projects.

Blog

Enhancing Offshore Operations with 3PE Anti-Corrosion Pipeline Technology

---

In the industrial pipeline sector, particularly for offshore applications, the integrity and durability of pipelines are of utmost importance. One prominent solution is the 3PE Anti-Corrosion Pipeline, which stands for Three-Layer Polyethylene coating. This technology is engineered to provide exceptional resistance against corrosion, ensuring the longevity of pipelines in harsh marine conditio