The Science Behind 3PE Coating and Its Impact on Steel Pipe Durability

2025-06-09

The Science Behind 3PE Coating and Its Impact on Steel Pipe Durability

Introduction to 3PE Coating Technology

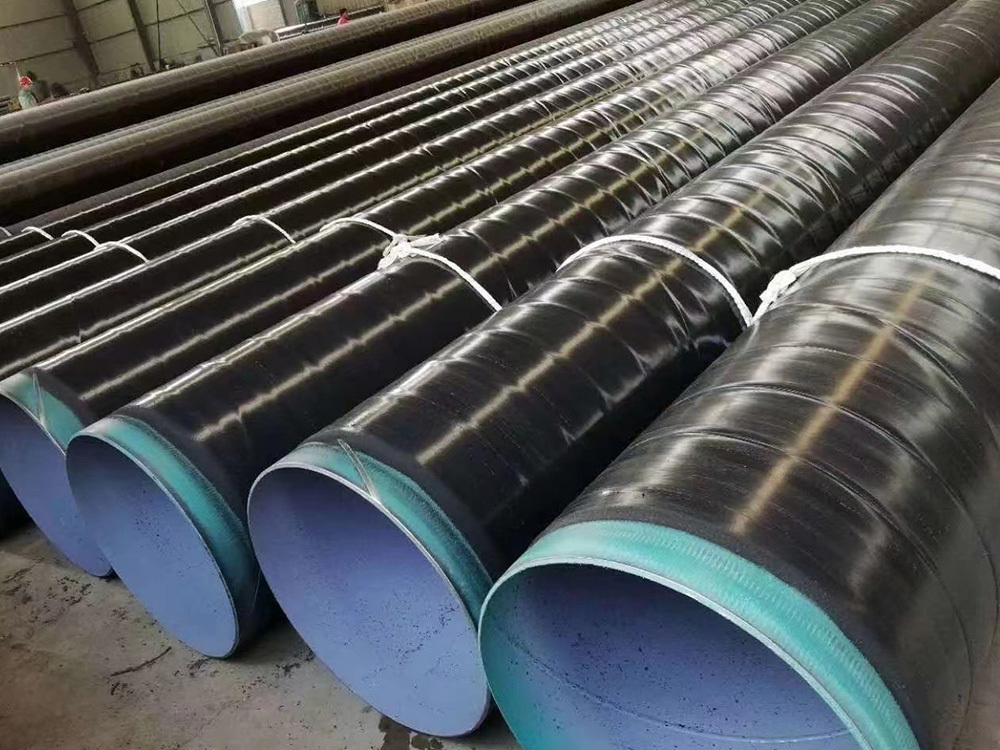

In the construction and manufacturing sectors, **steel pipes** are essential for numerous applications, from plumbing to oil and gas transportation. However, these pipes are inherently susceptible to corrosion, which can significantly reduce their lifespan and effectiveness. To combat this issue, the **3PE (Three-Layer Polyethylene)** coating system was developed. This revolutionary technology not only enhances the durability of steel pipes but also optimizes their performance in harsh environments.

Understanding 3PE Coating: Components and Application

The 3PE coating system consists of three distinct layers, each serving a unique purpose in protecting steel pipes:

1. Epoxy Primer Layer

The first layer, the **epoxy primer**, is crucial for adhesion. It bonds tightly to the steel surface, providing an excellent foundation for the subsequent layers. This layer is formulated to resist corrosion and acts as a barrier against moisture and environmental factors.

2. Adhesive Layer

The second layer is the **adhesive layer**, which ensures that the outer layer of polyethylene adheres firmly to the epoxy primer. This layer is essential for maintaining the integrity of the coating system, preventing delamination and ensuring a long-lasting bond.

3. Polyethylene Outer Layer

The final layer is the **polyethylene layer**, which provides the primary protection against mechanical damage, UV radiation, and chemical exposure. This robust outer layer is designed to withstand the rigors of external environments, making it ideal for both above-ground and underground applications.

The Application Process of 3PE Coating

The application of 3PE coating involves several critical steps, ensuring that each layer is applied correctly to achieve maximum performance.

1. Surface Preparation

Before applying the 3PE coating, the steel pipes must undergo thorough surface preparation. This step includes cleaning the surface to remove any rust, oil, or contaminants. Techniques such as sandblasting or shot blasting are commonly employed to achieve a clean, rough surface that promotes better adhesion.

2. Application of the Epoxy Primer

Once prepared, the epoxy primer is applied using methods such as spray, brush, or roller. This layer should be evenly distributed across the surface and allowed to cure according to the manufacturer's specifications.

3. Adhesive Layer Application

After the primer has cured, the adhesive layer is applied. This layer should be uniformly spread to ensure complete coverage and optimal bonding between the primer and the outer polyethylene layer.

4. Polyethylene Coating

Finally, the polyethylene layer is extruded over the adhesive layer, forming the outer protective barrier. This step requires precise control of temperature and pressure to ensure an even and consistent coating.

Benefits of 3PE Coating for Steel Pipes

The implementation of 3PE coating technology offers numerous benefits that significantly enhance steel pipe durability.

1. Superior Corrosion Resistance

One of the most notable advantages of 3PE coating is its exceptional resistance to corrosion. The multi-layered approach provides a robust barrier against moisture and corrosive substances, extending the life of steel pipes.

2. Enhanced Mechanical Protection

The tough polyethylene layer protects against physical damage from impacts and abrasions. This aspect is particularly beneficial in construction environments where pipes are subject to mechanical stress.

3. UV and Chemical Resistance

The polyethylene outer layer is highly resistant to UV radiation and various chemicals, ensuring that the pipes maintain their integrity even when exposed to harsh environmental conditions.

4. Cost-Effectiveness

Although the initial investment in 3PE coating may be higher than traditional coatings, the long-term cost savings result from reduced maintenance and replacement expenses. The extended lifespan of coated pipes translates to significant savings over time.

5. Environmental Benefits

3PE-coated pipes contribute to sustainability efforts by minimizing the need for frequent replacements and repairs, ultimately reducing waste in landfills. Furthermore, their durability reduces the likelihood of leaks, which can have detrimental effects on the environment.

Challenges and Considerations in 3PE Coating Application

Despite the numerous advantages, there are challenges and considerations associated with the application of 3PE coatings that must be addressed:

1. Application Conditions

The effectiveness of 3PE coating can be influenced by environmental factors such as temperature and humidity during application. It's crucial to adhere to the manufacturer's guidelines to ensure optimal conditions.

2. Surface Preparation Quality

The longevity of the 3PE coating heavily relies on the quality of surface preparation. Inadequate cleaning or preparation can lead to coating failure, emphasizing the importance of this initial step.

3. Skilled Labor Requirement

Applying 3PE coatings requires skilled labor and specialized equipment. Ensuring that personnel are adequately trained and that the right tools are used is essential for achieving the desired results.

Real-World Applications of 3PE Coated Steel Pipes

3PE-coated steel pipes are widely used across various industries, showcasing their versatility and effectiveness.

1. Oil and Gas Industry

In the oil and gas industry, 3PE-coated pipes are essential for transporting crude oil and natural gas. The coating's resistance to corrosion and mechanical damage makes it ideal for pipeline applications, ensuring the safe and efficient movement of these vital resources.

2. Water Supply Systems

Municipal water supply systems utilize 3PE-coated pipes to prevent corrosion and maintain water quality. The protective layer ensures that contaminants do not leach into the water supply, providing safe drinking water to communities.

3. Construction and Infrastructure

In construction projects, 3PE-coated pipes are often employed for drainage and sewage systems. Their durability and resistance to harsh chemicals make them suitable for a range of applications in urban infrastructure.

4. Industrial Applications

Various industrial applications, such as chemical processing and manufacturing, benefit from the use of 3PE-coated pipes. These pipes provide reliable service in environments where exposure to aggressive chemicals is commonplace.

Future Trends in 3PE Coating Technology

The field of coating technology is continually evolving, with new advancements enhancing the performance of 3PE coatings.

1. Smart Coatings

Emerging technologies are introducing smart coatings that can monitor the condition of steel pipes and provide real-time data on corrosion and wear. These innovations could revolutionize maintenance practices and improve safety.

2. Eco-Friendly Alternatives

As environmental concerns grow, the industry is exploring eco-friendly alternatives to traditional 3PE coatings. These sustainable options aim to maintain protective qualities while minimizing environmental impact.

3. Enhanced Adhesion Technologies

Research is ongoing to develop new adhesion technologies that further improve the bonding between layers in the 3PE coating system, enhancing durability and resistance to delamination.

FAQs about 3PE Coating and Steel Pipe Durability

1. What is 3PE coating, and how does it work?

3PE coating is a three-layer protective system for steel pipes consisting of an epoxy primer, an adhesive layer, and a polyethylene outer layer, designed to enhance corrosion resistance and durability.

2. How long does a 3PE coating last?

The lifespan of a 3PE coating can vary depending on environmental conditions and application quality, but it generally exceeds 30 years when properly applied and maintained.

3. Can 3PE coating be applied to existing steel pipes?

Yes, 3PE coating can be applied to existing steel pipes after proper surface preparation and cleaning to ensure effective adhesion.

4. Is 3PE coating environmentally friendly?

While 3PE coatings are not biodegradable, they reduce the frequency of pipe replacements and repairs, contributing to long-term sustainability efforts.

5. What industries benefit the most from 3PE-coated steel pipes?

Industries such as oil and gas, water supply, construction, and chemical processing significantly benefit from the durability and corrosion resistance provided by 3PE-coated steel pipes.

Conclusion

The **3PE coating** technology represents a significant advancement in the protection of steel pipes, effectively addressing corrosion, mechanical damage, and environmental challenges. By understanding the science behind this innovative coating system, industries can make informed decisions that enhance the durability and longevity of their infrastructure. As technologies continue to evolve, the role of 3PE coatings in ensuring the reliability of steel pipes will undoubtedly remain pivotal in various sectors, paving the way for a more sustainable and efficient future.

Blog

The Science Behind 3PE Coating and Its Impact on Steel Pipe Durability

The Science Behind 3PE Coating and Its Impact on Steel Pipe Durability

Introduction to 3PE Coating Technology

In the construction and manufacturing sectors, **steel pipes** are essential for numerous applications, from plumbing to oil and gas transportation. However, these pipes are inherently susceptible to corrosion, which can significantly reduce their lifespan and effectiveness. To combat this