The Essential Guide to 316L Stainless Steel Weld Neck Flanges

2025-06-29

When it comes to piping systems in construction, the choice of materials and components can significantly affect the overall performance and longevity of the installation. One such crucial component is the 316L stainless steel weld neck flange, which is widely utilized in various industries due to its exceptional properties.

316L stainless steel is an austenitic stainless steel known for its excellent corrosion resistance, particularly in chloride environments. This makes it particularly well-suited for applications in marine environments, chemical processing, and any area where exposure to corrosive substances is a concern. The 'L' in 316L indicates a lower carbon content, which enhances its weldability and reduces the risk of carbide precipitation during welding. This characteristic is particularly important in maintaining the corrosion resistance of the welded joints, ensuring the integrity of the piping system.

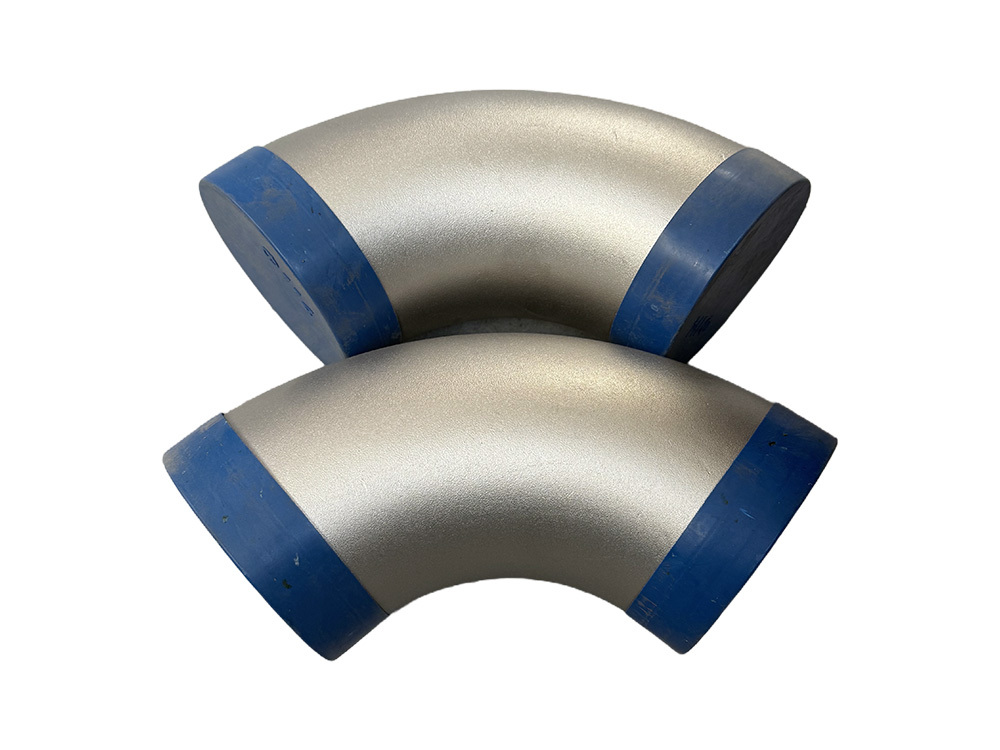

A weld neck flange features a long tapered neck that is designed to be welded to the pipe. This design provides a strong and stable connection that can endure high pressures and temperatures, making it an excellent choice for demanding applications. The smooth transition from the flange to the pipe minimizes turbulence and flow resistance, allowing for efficient fluid movement within the system. Furthermore, the weld neck flange can accommodate various pipe sizes, providing versatility in design and application.

In addition to its functional benefits, the 316L stainless steel weld neck flange is also appreciated for its aesthetic qualities. The polished finish of stainless steel offers a visually appealing appearance, making it suitable for architectural applications where both form and function are essential. Whether used in exposed piping systems or as part of decorative installations, these flanges contribute to the overall design while maintaining reliability.

Another advantage of using 316L stainless steel weld neck flanges is their compatibility with a range of other materials. This flexibility allows for the integration of different pipes and fittings, facilitating easier installations and repairs. Additionally, these flanges can withstand extreme temperatures and pressures, making them ideal for industrial applications, including oil and gas, power generation, and water treatment facilities.

In conclusion, the 316L stainless steel weld neck flange is a critical component in modern piping systems, offering unparalleled strength, durability, and resistance to corrosion. Its design and material properties make it suitable for a wide range of applications, ensuring that it remains a popular choice among engineers and builders alike. Understanding the benefits of this flange type can help in making informed decisions when planning and executing construction projects, ultimately leading to safer and more efficient installations.

316L stainless steel is an austenitic stainless steel known for its excellent corrosion resistance, particularly in chloride environments. This makes it particularly well-suited for applications in marine environments, chemical processing, and any area where exposure to corrosive substances is a concern. The 'L' in 316L indicates a lower carbon content, which enhances its weldability and reduces the risk of carbide precipitation during welding. This characteristic is particularly important in maintaining the corrosion resistance of the welded joints, ensuring the integrity of the piping system.

A weld neck flange features a long tapered neck that is designed to be welded to the pipe. This design provides a strong and stable connection that can endure high pressures and temperatures, making it an excellent choice for demanding applications. The smooth transition from the flange to the pipe minimizes turbulence and flow resistance, allowing for efficient fluid movement within the system. Furthermore, the weld neck flange can accommodate various pipe sizes, providing versatility in design and application.

In addition to its functional benefits, the 316L stainless steel weld neck flange is also appreciated for its aesthetic qualities. The polished finish of stainless steel offers a visually appealing appearance, making it suitable for architectural applications where both form and function are essential. Whether used in exposed piping systems or as part of decorative installations, these flanges contribute to the overall design while maintaining reliability.

Another advantage of using 316L stainless steel weld neck flanges is their compatibility with a range of other materials. This flexibility allows for the integration of different pipes and fittings, facilitating easier installations and repairs. Additionally, these flanges can withstand extreme temperatures and pressures, making them ideal for industrial applications, including oil and gas, power generation, and water treatment facilities.

In conclusion, the 316L stainless steel weld neck flange is a critical component in modern piping systems, offering unparalleled strength, durability, and resistance to corrosion. Its design and material properties make it suitable for a wide range of applications, ensuring that it remains a popular choice among engineers and builders alike. Understanding the benefits of this flange type can help in making informed decisions when planning and executing construction projects, ultimately leading to safer and more efficient installations.

Blog

The Essential Guide to 316L Stainless Steel Weld Neck Flanges

When it comes to piping systems in construction, the choice of materials and components can significantly affect the overall performance and longevity of the installation. One such crucial component is the 316L stainless steel weld neck flange, which is widely utilized in various industries due to its exceptional properties.

316L stainless steel is an austenitic stainless steel known for its excel