Exploring the Versatility of ASTM A403 Stainless Steel Tee in Design

2025-06-25

Exploring the Versatility of ASTM A403 Stainless Steel Tee in Design

Table of Contents

- 1. Introduction to ASTM A403 Stainless Steel Tee

- 2. Key Properties of ASTM A403 Stainless Steel Tee

- 3. Applications of ASTM A403 Stainless Steel Tee

- 4. Design Considerations for ASTM A403 Stainless Steel Tee

- 5. Installation Guidelines for ASTM A403 Stainless Steel Tee

- 6. Maintenance of ASTM A403 Stainless Steel Tee

- 7. Advantages of Using ASTM A403 Stainless Steel Tee

- 8. Conclusion

- 9. FAQs about ASTM A403 Stainless Steel Tee

1. Introduction to ASTM A403 Stainless Steel Tee

ASTM A403 stainless steel tees play a crucial role in various piping systems, offering an exceptional combination of strength, durability, and versatility. These fittings are primarily used in the construction and decoration of pipelines, serving as a fundamental component in fluid transfer systems. The ASTM A403 standard specifies the requirements for wrought austenitic stainless steel fittings, which are widely accepted and utilized in numerous industries. This article explores the versatility of ASTM A403 stainless steel tees, showcasing their properties, applications, and design considerations.

2. Key Properties of ASTM A403 Stainless Steel Tee

ASTM A403 stainless steel tees possess several key properties that make them a preferred choice for many applications:

2.1 Corrosion Resistance

The austenitic composition of ASTM A403 stainless steel provides excellent corrosion resistance. This property is essential for applications in chemical processing, marine environments, and other settings where exposure to corrosive substances is prevalent.

2.2 High Strength and Durability

These tees are manufactured to withstand high pressures and temperatures, making them suitable for demanding industrial applications. Their durability ensures a long service life, reducing the need for frequent replacements.

2.3 Temperature Resistance

ASTM A403 stainless steel can maintain its mechanical properties at elevated temperatures, making it ideal for use in high-temperature applications, such as power plants and refineries.

2.4 Ease of Fabrication

The material can be easily welded, bent, and fabricated into various shapes and sizes, allowing for greater flexibility in design and installation.

3. Applications of ASTM A403 Stainless Steel Tee

The versatility of ASTM A403 stainless steel tees allows for their use across different industries. Below are some of the primary applications:

3.1 Industrial Applications

In industrial settings, ASTM A403 stainless steel tees are commonly used in piping systems for the transportation of fluids, gases, and chemicals. Industries such as oil and gas, chemical processing, and pharmaceuticals rely heavily on these fittings due to their durability and resistance to corrosion.

3.2 Commercial Uses

In commercial settings, these tees are often found in HVAC systems, plumbing infrastructures, and fire protection systems. Their ability to handle various pressure levels and temperatures makes them ideal for ensuring efficient operation in commercial buildings.

3.3 Residential Applications

Within residential settings, ASTM A403 stainless steel tees can be utilized in water supply systems, drainage systems, and even decorative applications where a modern aesthetic is desired. Their visual appeal combined with functional properties enhances overall design.

4. Design Considerations for ASTM A403 Stainless Steel Tee

When incorporating ASTM A403 stainless steel tees into a design plan, several factors must be considered:

4.1 Size and Dimensions

Selecting the appropriate size and dimension is crucial for ensuring optimal flow rates and system efficiency. The design should account for future expansions and modifications as well.

4.2 Compatibility with Other Materials

It is essential to ensure that ASTM A403 stainless steel tees are compatible with other materials in the piping system to prevent galvanic corrosion. Proper selection of joint materials and fittings is necessary.

4.3 Aesthetic Considerations

For applications that require aesthetic appeal, it is essential to consider the finish and appearance of the stainless steel tees. Polished finishes can enhance visual appeal in exposed piping systems.

5. Installation Guidelines for ASTM A403 Stainless Steel Tee

Installing ASTM A403 stainless steel tees requires adherence to specific guidelines to ensure optimal performance:

5.1 Proper Tools and Equipment

Utilizing the right tools and equipment for installation is crucial. This includes using suitable welding techniques, such as TIG welding, to create strong joints.

5.2 Follow Manufacturer Instructions

Always adhere to the manufacturer’s guidelines regarding installation methods and torque specifications to ensure structural integrity.

5.3 Inspection and Testing

Post-installation, it is vital to conduct thorough inspections and pressure testing to verify the integrity of the piping system and the fittings.

6. Maintenance of ASTM A403 Stainless Steel Tee

To ensure longevity and reliable performance, regular maintenance of ASTM A403 stainless steel tees is recommended:

6.1 Routine Inspections

Conduct routine inspections to check for signs of wear, corrosion, or leaks. Early detection can prevent more significant issues down the line.

6.2 Cleaning Procedures

Cleaning the fittings with non-abrasive materials can help maintain their appearance and prevent the buildup of corrosive substances.

6.3 Replacement of Damaged Components

If any fittings show significant signs of damage or corrosion, replacing them promptly is essential to maintain system integrity.

7. Advantages of Using ASTM A403 Stainless Steel Tee

The benefits of utilizing ASTM A403 stainless steel tees in design and installation are numerous:

7.1 Cost-Effectiveness

While the initial investment may be higher compared to other materials, the longevity, durability, and low maintenance requirements of stainless steel tees often translate to lower lifetime costs.

7.2 Versatile Applications

Their adaptability allows ASTM A403 stainless steel tees to be used across various industries, catering to unique requirements and enhancing project flexibility.

7.3 Enhanced Safety

The high strength and corrosion resistance of these tees contribute to safer piping systems, reducing the risk of leaks and failures.

8. Conclusion

In conclusion, ASTM A403 stainless steel tees are indispensable components in modern piping systems, offering a unique blend of strength, durability, and versatility. Their diverse applications across industrial, commercial, and residential settings highlight their importance in effective fluid transfer. By understanding their properties, installation requirements, and maintenance needs, design professionals can make informed decisions that enhance the efficiency and safety of their projects. Investing in ASTM A403 stainless steel tees ensures long-lasting performance and reliability, making them a top choice for piping solutions.

9. FAQs about ASTM A403 Stainless Steel Tee

What is ASTM A403?

ASTM A403 is a standard specification for wrought austenitic stainless steel fittings, which are commonly used in piping systems.

What are the benefits of using stainless steel tees?

Stainless steel tees offer excellent corrosion resistance, high strength, durability, and versatility, making them suitable for various applications.

How do I choose the right size ASTM A403 tee?

Selecting the correct size involves considering the flow rates, pressure requirements, and compatibility with existing piping systems.

Can ASTM A403 stainless steel tees be welded?

Yes, ASTM A403 stainless steel tees are designed for easy welding, allowing for strong and reliable connections in piping systems.

What maintenance is required for ASTM A403 stainless steel tees?

Routine inspections, proper cleaning, and prompt replacement of damaged components are essential for maintaining the longevity of ASTM A403 stainless steel tees.

Blog

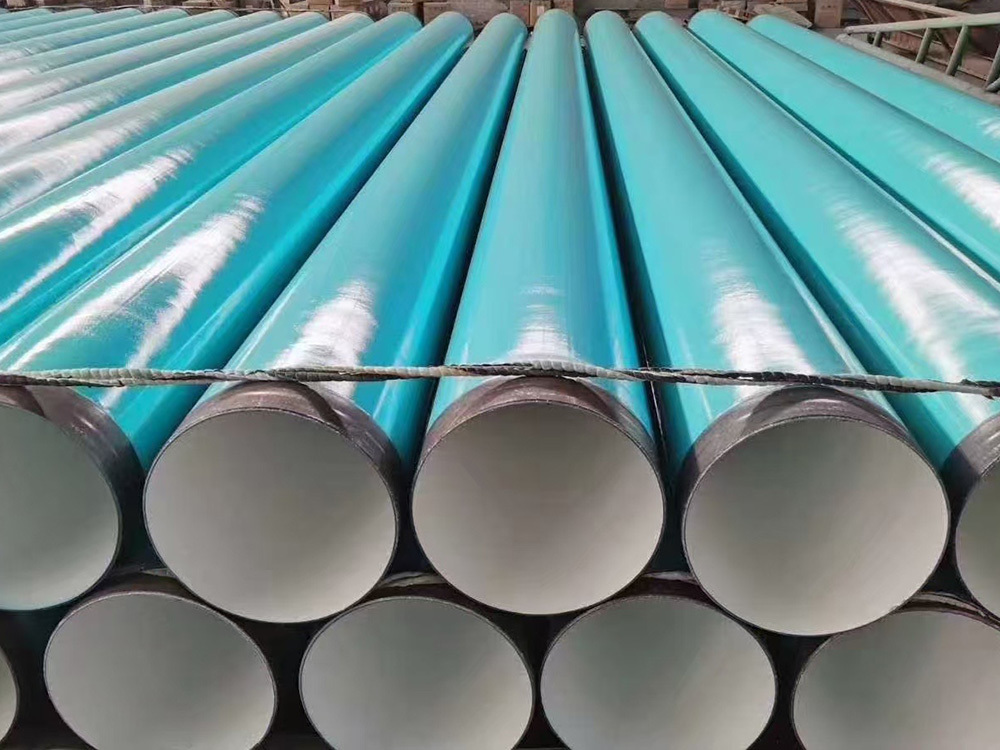

Exploring the Benefits of 3PE Anti-Corrosion Pipeline for Offshore Applications

In the realm of industrial equipment and components, particularly in the pipeline sector, the integrity and durability of pipelines are paramount, especially for offshore applications. One of the most significant advancements in pipeline technology is the development of the 3PE (three-layer polyethylene) anti-corrosion pipeline, which provides an effective solution for combating corrosion in chall