Underground Pipe Installation: The Essential Role of 3PE Coated Steel in Modern Construction

2025-06-01

Underground Pipe Installation: The Essential Role of 3PE Coated Steel in Modern Construction

Table of Contents

- 1. Introduction

- 2. Understanding 3PE Coating

- 3. Importance of Underground Pipe Installation

- 4. The Role of 3PE Coated Steel in Underground Pipe Installation

- 5. Installation Techniques for 3PE Coated Steel Pipes

- 6. Best Practices for Using 3PE Coated Steel Pipes

- 7. Cost Considerations for 3PE Coated Steel Pipes

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction

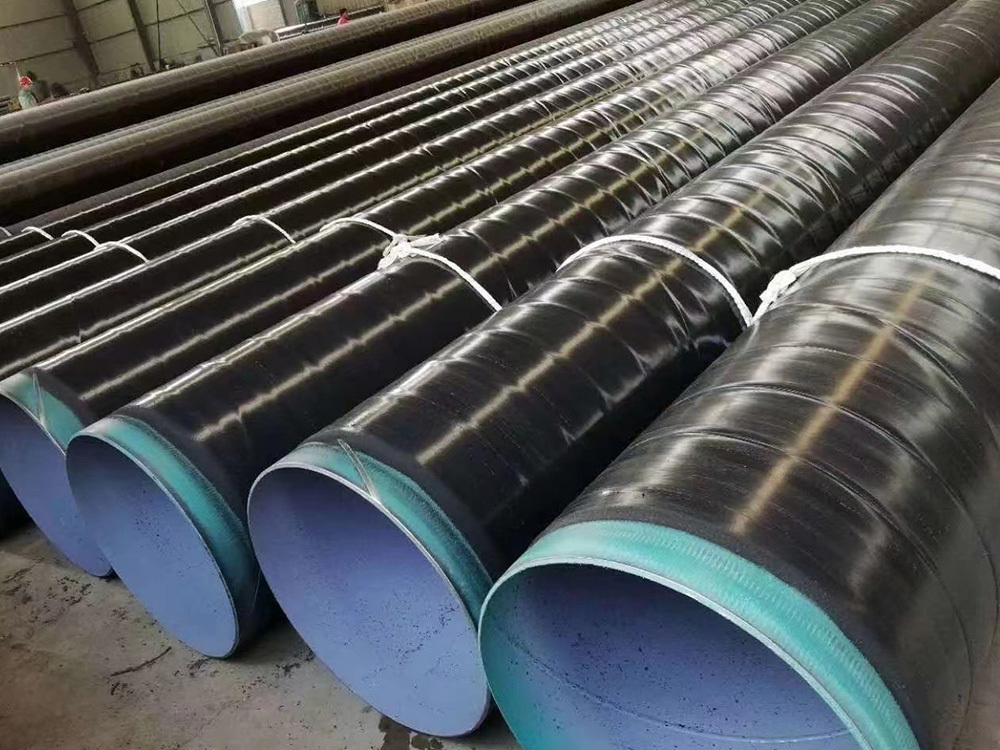

In the realm of modern construction, **underground pipe installation** is a critical aspect that ensures the effective delivery of water, sewage, and other essential utilities. As we delve into the intricacies of this process, it becomes evident that the choice of materials plays a pivotal role in the overall success and longevity of infrastructure projects. **3PE (Three-Layer Polyethylene) coated steel pipes** have emerged as a preferred choice for professionals in the construction industry due to their robustness, durability, and superior corrosion resistance. This article aims to provide a detailed overview of the significance of 3PE coated steel in underground pipe installation, exploring its advantages, installation methods, and best practices.

2. Understanding 3PE Coating

To appreciate the benefits of 3PE coated steel, it is essential to comprehend what 3PE coating entails, including its components and advantages.

2.1 Components of 3PE Coating

3PE coating consists of three distinct layers:

1. **Epoxy Primer**: The first layer is an epoxy coating that adheres to the steel surface, providing an initial barrier against corrosion.

2. **Polyethylene Layer**: The second layer is a thick polyethylene coating that protects the epoxy layer and adds physical strength to the pipe.

3. **Outer Polyethylene Layer**: The outermost layer is another polyethylene coating that provides additional protection against environmental factors, ensuring durability and longevity.

Each layer plays a crucial role in enhancing the overall performance of the pipe, making it an ideal choice for underground installations.

2.2 Benefits of 3PE Coating

The advantages of using 3PE coated steel pipes in construction are numerous:

- **Corrosion Resistance**: The multi-layered structure effectively prevents corrosion, extending the lifespan of the pipes.

- **Mechanical Strength**: The polyethylene layers provide excellent mechanical strength, allowing the pipes to withstand external pressures and impacts.

- **Ease of Installation**: The lightweight nature of 3PE coated pipes simplifies the installation process, reducing labor costs and time.

- **Environmental Protection**: The robust outer layer protects against harsh environmental conditions, ensuring the integrity of the pipes over time.

3. Importance of Underground Pipe Installation

Underground pipe installation is vital for several reasons, including:

- **Utility Distribution**: It ensures the efficient distribution of essential services such as water supply, drainage, and sewage management.

- **Space Optimization**: By installing pipes underground, construction projects can maximize above-ground space for other essential infrastructure.

- **Aesthetic Value**: Underground installations enhance the aesthetic appeal of construction sites by eliminating visible pipes and fittings.

3.1 Types of Pipes Used

In addition to 3PE coated steel pipes, several other types of pipes are commonly used in underground installations:

- **PVC Pipes**: Lightweight and resistant to corrosion, PVC pipes are often used for water supply and drainage systems.

- **Ductile Iron Pipes**: Known for their strength and durability, ductile iron pipes are frequently used in sewage and water distribution systems.

- **HDPE Pipes**: High-Density Polyethylene (HDPE) pipes are flexible and offer excellent resistance to chemicals, making them suitable for various applications.

Each type of pipe has its own set of advantages and is chosen based on specific project requirements.

3.2 Challenges in Installation

While underground pipe installation is essential, it also presents various challenges:

- **Soil Conditions**: The type of soil can significantly impact the installation process, affecting the choice of pipe and installation techniques.

- **Depth and Accessibility**: Installing pipes at significant depths or in hard-to-reach areas can complicate the installation process.

- **Environmental Regulations**: Compliance with local environmental regulations can impose additional requirements for pipe installation, affecting timelines and costs.

4. The Role of 3PE Coated Steel in Underground Pipe Installation

3PE coated steel pipes have become increasingly popular in underground installations due to their outstanding performance and reliability.

4.1 Durability and Longevity

One of the most significant advantages of 3PE coated steel pipes is their durability. The combination of steel and a protective coating ensures these pipes can withstand harsh environmental conditions, including soil acidity, moisture, and temperature fluctuations. This durability translates into a longer service life, reducing the need for frequent replacements and repairs.

4.2 Corrosion Resistance

Corrosion is a leading cause of pipe failure, particularly in underground installations. The epoxy primer and protective polyethylene layers of 3PE coated steel provide a formidable defense against corrosion. This attribute not only extends the lifespan of the pipes but also significantly reduces maintenance costs, making 3PE coated steel a cost-effective solution for construction projects.

5. Installation Techniques for 3PE Coated Steel Pipes

Proper installation techniques are crucial to maximizing the benefits of 3PE coated steel pipes in underground applications.

5.1 Pre-Installation Preparation

Before installation, several preparatory steps should be undertaken:

- **Site Inspection**: Conduct a thorough inspection of the installation site to assess soil conditions and identify potential challenges.

- **Material Verification**: Ensure that all materials, including 3PE coated pipes and fittings, meet industry standards and project specifications.

- **Planning**: Develop a detailed installation plan that outlines the layout and installation sequence, taking into consideration any environmental regulations.

5.2 Installation Process

The installation process for 3PE coated steel pipes typically involves the following steps:

1. **Excavation**: Carefully excavate the area where the pipes will be installed, ensuring minimal disturbance to the surrounding environment.

2. **Pipe Assembly**: Assemble the pipes and fittings according to the installation plan, utilizing appropriate tools and techniques to ensure secure connections.

3. **Backfilling**: Once the pipes are installed, backfill the trench with suitable material, ensuring proper compaction to prevent future settling.

5.3 Post-Installation Testing

After installation, it is essential to conduct thorough testing to ensure the integrity and functionality of the system. Common tests include:

- **Hydrostatic Testing**: This test involves filling the pipes with water to check for leaks and ensure they can withstand pressure.

- **Visual Inspections**: Inspect the installation for any visible signs of damage or improper installation.

- **Documentation**: Maintain comprehensive records of the installation process and testing results for future reference.

6. Best Practices for Using 3PE Coated Steel Pipes

To optimize the use of 3PE coated steel pipes in underground installations, consider the following best practices:

- **Follow Manufacturer Guidelines**: Adhere to the manufacturer’s recommendations for installation, handling, and maintenance.

- **Regular Inspections**: Schedule regular inspections to monitor the condition of the pipes and identify any potential issues early.

- **Training and Certification**: Ensure that all personnel involved in the installation process are appropriately trained and certified in handling and installing 3PE coated steel pipes.

7. Cost Considerations for 3PE Coated Steel Pipes

While 3PE coated steel pipes may have a higher upfront cost compared to other materials, their long-term benefits often outweigh the initial investment. Consider the following cost factors:

- **Material Cost**: Evaluate the cost of 3PE coated steel pipes compared to alternative materials, factoring in the benefits of durability and corrosion resistance.

- **Installation Costs**: Analyze labor costs associated with the installation of 3PE coated pipes, including any specialized training required.

- **Maintenance and Replacement Costs**: Account for potential savings in maintenance and replacement costs due to the longevity and reliability of 3PE coated steel pipes.

8. Frequently Asked Questions

1. What is 3PE coating?

3PE coating is a three-layer protective coating for steel pipes, consisting of an epoxy primer, a polyethylene layer, and an outer polyethylene layer that provides enhanced corrosion resistance and mechanical strength.

2. Why are 3PE coated steel pipes preferred for underground installations?

3PE coated steel pipes are preferred due to their durability, corrosion resistance, and ability to withstand harsh environmental conditions, making them ideal for long-term underground applications.

3. How does installation of 3PE coated steel pipes differ from other types of pipes?

The installation process for 3PE coated steel pipes involves similar techniques as other pipes but requires attention to detail regarding the handling of the coated surfaces to prevent damage.

4. What testing is required after installing 3PE coated steel pipes?

Post-installation testing typically includes hydrostatic testing to check for leaks and visual inspections to ensure proper installation.

5. Are there any environmental concerns with 3PE coated steel pipes?

3PE coated steel pipes are designed to withstand environmental factors and comply with regulations, reducing the risk of environmental contamination compared to other materials.

9. Conclusion

In conclusion, the role of **3PE coated steel pipes** in underground pipe installation is indispensable for modern construction projects. Their durability, corrosion resistance, and ease of installation make them a superior choice for ensuring reliable utility distribution while maximizing the lifespan of the infrastructure. By understanding the installation techniques, adhering to best practices, and considering cost implications, construction professionals can confidently choose 3PE coated steel pipes for their underground projects, ultimately leading to successful and sustainable construction outcomes.

Blog

Understanding Polyurethane Direct Buried Insulation Pipes: Key Benefits and Applications