Understanding Polyurethane Direct Buried Insulation Pipes: Key Benefits and Applications

2025-06-13

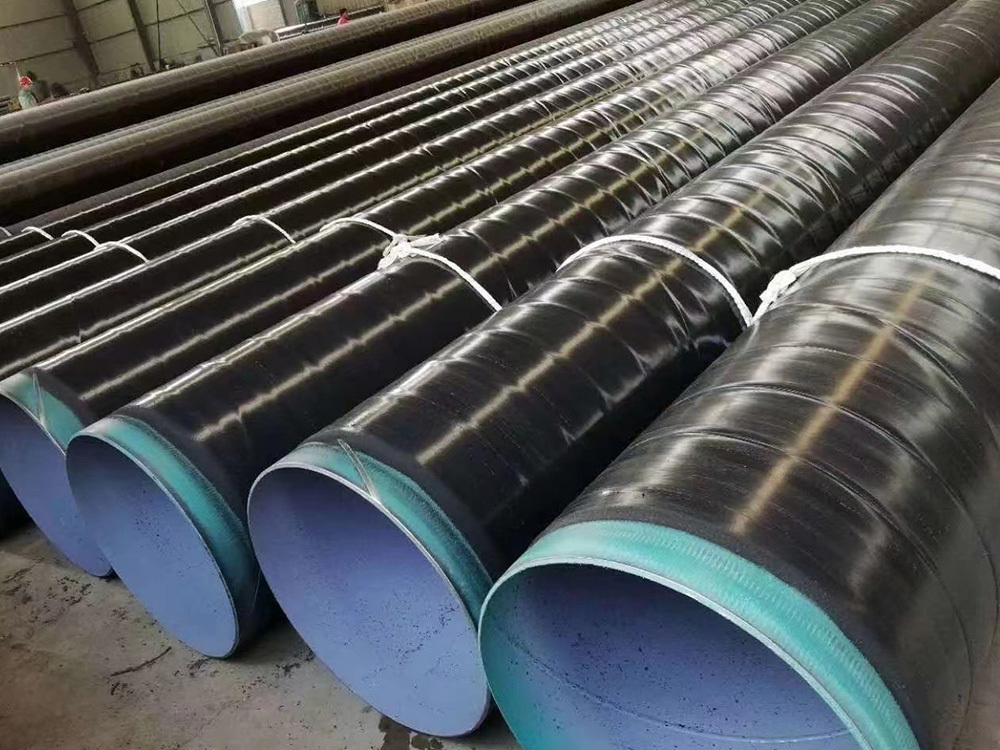

Polyurethane direct buried insulation pipes are critical components in modern insulation technology, especially within the metallurgy, mining, and energy sectors. These pipes are designed for the transportation of fluids at varying temperatures, ensuring minimal heat loss and optimal energy efficiency.

One of the primary advantages of polyurethane direct buried insulation pipes is their exceptional thermal insulation properties. The polyurethane foam used in these pipes provides a high level of thermal resistance, allowing them to maintain the desired temperature of the transported fluids. This characteristic is particularly beneficial in applications where heat retention is crucial, such as in district heating systems, industrial process heating, and chilled water distribution.

Another significant benefit of these insulation pipes is their durability and resistance to environmental factors. Polyurethane is inherently resistant to moisture, chemicals, and extreme temperature variations, making it suitable for direct burial applications. This resilience ensures that the pipes can withstand harsh conditions without compromising their structural integrity or insulation performance. Furthermore, the lightweight nature of polyurethane reduces the overall installation burden, facilitating easier handling and installation in remote or difficult-to-reach locations.

From an environmental standpoint, using polyurethane direct buried insulation pipes can lead to significant energy savings. By minimizing heat loss during fluid transportation, these pipes contribute to reduced energy consumption and lower greenhouse gas emissions. This aligns well with the increasing global emphasis on sustainability and energy efficiency in industrial practices.

In terms of installation, polyurethane insulation pipes can be tailored to meet specific project requirements. They come in various diameters and lengths, making them adaptable to a wide range of applications. Additionally, their flexibility allows for ease of installation in complex configurations, further enhancing their usability in diverse environments.

Maintenance of polyurethane direct buried insulation pipes is generally straightforward due to their robust design. Regular inspections can help identify any potential issues early on, ensuring long-term functionality and performance. Moreover, the reduction in heat loss not only leads to energy savings but also simplifies the management of temperature-sensitive processes.

In summary, polyurethane direct buried insulation pipes offer a combination of superior thermal insulation, durability, and environmental benefits, making them an excellent choice for various applications in the metallurgy, mining, and energy sectors. Their efficiency in maintaining fluid temperatures and reducing energy losses aligns perfectly with contemporary industry demands for sustainability and cost-effectiveness. By incorporating these advanced insulation solutions, companies can enhance their operational efficiency while contributing positively to environmental protection.

Blog

Understanding Polyurethane Direct Buried Insulation Pipes: Key Benefits and Applications