Exploring the Benefits of 3PE Anti-Corrosion Pipeline for Offshore Applications

2025-07-15

In the realm of industrial equipment and components, particularly in the pipeline sector, the integrity and durability of pipelines are paramount, especially for offshore applications. One of the most significant advancements in pipeline technology is the development of the 3PE (three-layer polyethylene) anti-corrosion pipeline, which provides an effective solution for combating corrosion in challenging environments.

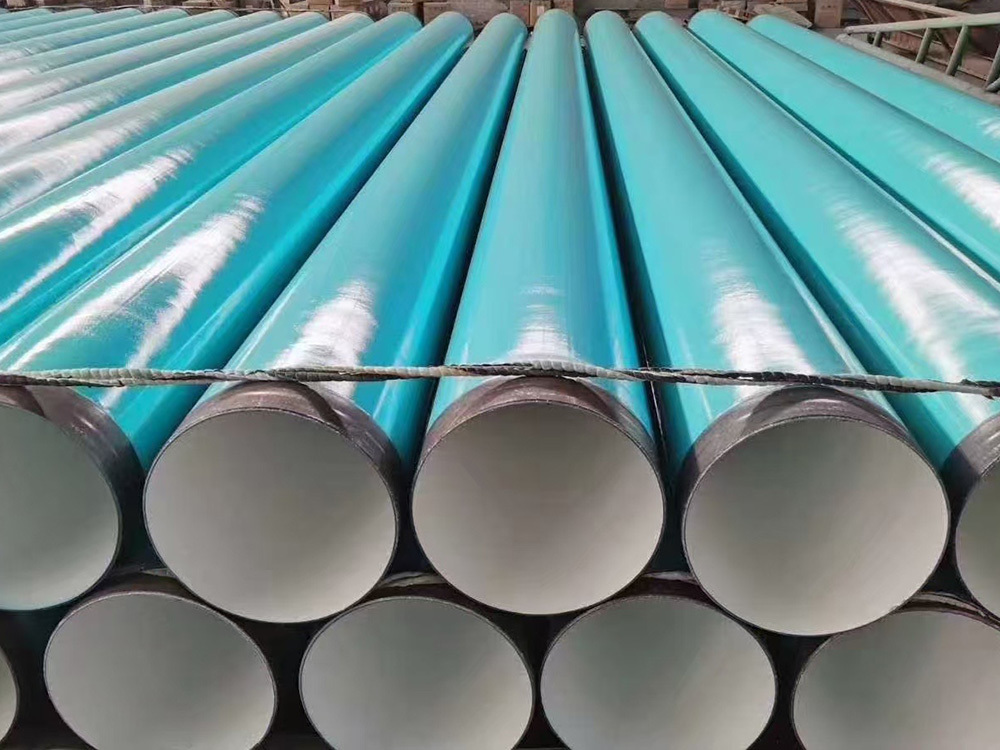

The 3PE anti-corrosion pipeline consists of three layers: an epoxy primer layer that adheres to the steel surface, a middle layer of adhesive that ensures a strong bond, and an outer layer of polyethylene that offers excellent protection against moisture and aggressive substances. This multi-layered approach not only enhances the structural integrity of the pipeline but also significantly extends its lifespan, making it ideal for offshore applications where exposure to seawater and harsh weather conditions can lead to accelerated degradation.

One of the primary advantages of using 3PE anti-corrosion pipelines in offshore settings is their remarkable resistance to corrosive elements. The marine environment presents unique challenges, such as saltwater exposure and varying temperatures, which can lead to rust and deterioration if proper precautions are not taken. The robust protective layers of the 3PE pipeline effectively shield the underlying steel from these corrosive agents, reducing maintenance costs and the risk of pipeline failure.

Moreover, 3PE coatings exhibit excellent adhesion to various substrates, ensuring that the protective layers remain intact even under extreme conditions. This is particularly crucial in offshore applications where pipelines are subjected to vibrations, temperature fluctuations, and mechanical stress. The durable nature of 3PE coatings allows pipelines to maintain their integrity, ensuring uninterrupted operations.

In addition to their protective qualities, 3PE anti-corrosion pipelines also contribute to the overall efficiency of offshore operations. By minimizing the need for frequent repairs and replacements due to corrosion, companies can optimize their resource allocation and focus on their core activities. This leads to improved productivity and reduced downtime, which are critical factors in the highly competitive offshore industry.

Furthermore, the application of 3PE technology is versatile, making it suitable for various pipeline diameters and configurations. Whether for transporting oil, gas, or water, these pipelines can be customized to meet specific operational requirements while ensuring reliable performance.

In conclusion, adopting 3PE anti-corrosion pipelines in offshore applications presents a significant opportunity for enhancing pipeline longevity, reducing maintenance costs, and improving overall operational efficiency. Companies looking to invest in durable and effective pipeline solutions should consider the many benefits that 3PE technology offers in combating the challenges posed by corrosive marine environments. With the right technology, businesses can ensure the reliability and safety of their operations while thriving in the offshore sector.

The 3PE anti-corrosion pipeline consists of three layers: an epoxy primer layer that adheres to the steel surface, a middle layer of adhesive that ensures a strong bond, and an outer layer of polyethylene that offers excellent protection against moisture and aggressive substances. This multi-layered approach not only enhances the structural integrity of the pipeline but also significantly extends its lifespan, making it ideal for offshore applications where exposure to seawater and harsh weather conditions can lead to accelerated degradation.

One of the primary advantages of using 3PE anti-corrosion pipelines in offshore settings is their remarkable resistance to corrosive elements. The marine environment presents unique challenges, such as saltwater exposure and varying temperatures, which can lead to rust and deterioration if proper precautions are not taken. The robust protective layers of the 3PE pipeline effectively shield the underlying steel from these corrosive agents, reducing maintenance costs and the risk of pipeline failure.

Moreover, 3PE coatings exhibit excellent adhesion to various substrates, ensuring that the protective layers remain intact even under extreme conditions. This is particularly crucial in offshore applications where pipelines are subjected to vibrations, temperature fluctuations, and mechanical stress. The durable nature of 3PE coatings allows pipelines to maintain their integrity, ensuring uninterrupted operations.

In addition to their protective qualities, 3PE anti-corrosion pipelines also contribute to the overall efficiency of offshore operations. By minimizing the need for frequent repairs and replacements due to corrosion, companies can optimize their resource allocation and focus on their core activities. This leads to improved productivity and reduced downtime, which are critical factors in the highly competitive offshore industry.

Furthermore, the application of 3PE technology is versatile, making it suitable for various pipeline diameters and configurations. Whether for transporting oil, gas, or water, these pipelines can be customized to meet specific operational requirements while ensuring reliable performance.

In conclusion, adopting 3PE anti-corrosion pipelines in offshore applications presents a significant opportunity for enhancing pipeline longevity, reducing maintenance costs, and improving overall operational efficiency. Companies looking to invest in durable and effective pipeline solutions should consider the many benefits that 3PE technology offers in combating the challenges posed by corrosive marine environments. With the right technology, businesses can ensure the reliability and safety of their operations while thriving in the offshore sector.

Blog

Exploring the Benefits of 3PE Anti-Corrosion Pipeline for Offshore Applications

In the realm of industrial equipment and components, particularly in the pipeline sector, the integrity and durability of pipelines are paramount, especially for offshore applications. One of the most significant advancements in pipeline technology is the development of the 3PE (three-layer polyethylene) anti-corrosion pipeline, which provides an effective solution for combating corrosion in chall