Top Reasons to Opt for 3PE Coated Steel Pipes in Your Underground Projects

2025-07-11

Top Reasons to Opt for 3PE Coated Steel Pipes in Your Underground Projects

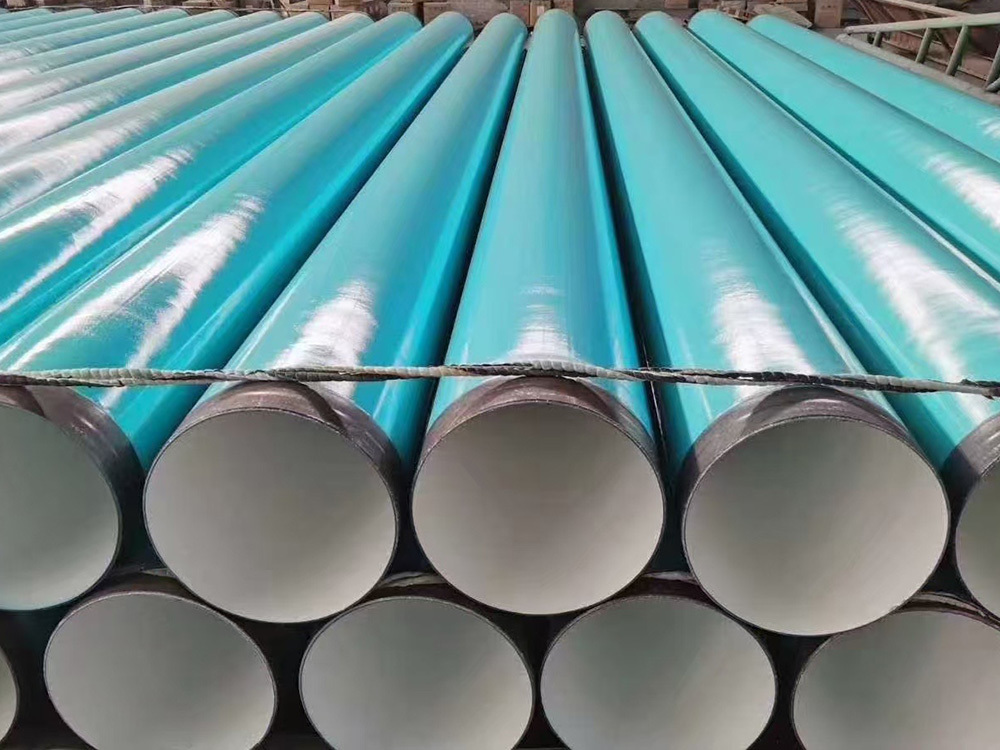

Introduction to 3PE Coated Steel Pipes

In the construction industry, selecting the right materials is crucial for ensuring durability, safety, and cost-effectiveness. When it comes to underground projects, **3PE (Triple Layer Polyethylene) coated steel pipes** stand out as an excellent choice. This innovative solution not only enhances the longevity of pipelines but also offers significant benefits over traditional materials. This article delves deep into the **top reasons to opt for 3PE coated steel pipes** for your underground projects.

Understanding 3PE Coating: What It Is and How It Works

3PE coating consists of three layers: an epoxy primer, a polyethylene adhesive, and a high-density polyethylene layer. This combination is specifically designed to provide excellent corrosion protection and mechanical resistance. Let’s explore how each layer contributes to the overall performance of the pipes.

The Epoxy Primer Layer

The first layer consists of an epoxy primer, which adheres well to the steel substrate, creating a strong bond that protects against corrosion. This layer also enhances the pipe's resistance to chemicals and extreme weather conditions.

The Adhesive Layer

Next, the adhesive layer serves to bind the primer layer to the polyethylene layer. This intermediate layer is crucial for ensuring that the coatings remain intact, even under high-stress conditions.

The Polyethylene Layer

Finally, the outer layer of high-density polyethylene provides a robust barrier against environmental factors. This layer is not only resistant to moisture but also protects the pipes from mechanical damage during installation and operation.

Advantages of Using 3PE Coated Steel Pipes

Choosing 3PE coated steel pipes for your underground projects offers numerous advantages that can significantly impact the overall success of your construction endeavors.

1. Exceptional Corrosion Resistance

Corrosion is one of the leading causes of pipeline failure, especially in underground environments. The **3PE coating** provides a protective barrier that prevents moisture and corrosive substances from coming into contact with the steel. This ensures that the pipes maintain their structural integrity over time, reducing the need for repairs and replacements.

2. Enhanced Durability and Longevity

3PE coated steel pipes are designed to withstand harsh conditions, including soil movement, temperature fluctuations, and chemical exposure. By opting for these pipes, you can expect a longer lifespan, leading to reduced costs associated with maintenance and replacement.

3. Cost-Effectiveness Over Time

While the initial investment in 3PE coated steel pipes may be higher than traditional options, the long-term savings are significant. Their durability and resistance to corrosion mean fewer repairs and replacements, ultimately lowering overall project costs.

4. Easy Installation Process

3PE coated steel pipes are lightweight and designed for easy handling, which streamlines the installation process. This not only saves time on the job site but also reduces labor costs, making it an attractive option for contractors.

5. Environmentally Friendly Option

With increasing awareness of environmental issues, choosing materials that are sustainable and recyclable is crucial. 3PE coated steel pipes can be recycled at the end of their life cycle, contributing to a more sustainable construction approach.

Applications of 3PE Coated Steel Pipes in Underground Projects

3PE coated steel pipes are versatile and can be employed in various underground applications, including:

1. Water and Wastewater Management

These pipes are ideal for transporting potable water and managing wastewater due to their corrosion resistance and durability.

2. Oil and Gas Industries

In the oil and gas sector, pipelines must withstand extreme conditions. 3PE coated steel pipes provide the necessary protection against corrosive substances found in these environments.

3. Heating and Cooling Systems

For underground heating and cooling systems, the robust nature of 3PE coated pipes ensures efficient energy transfer while maintaining long-term reliability.

Comparative Analysis: 3PE Coated Steel Pipes vs. Other Coated Pipes

When evaluating options for underground projects, it’s essential to compare the benefits of 3PE coated steel pipes with other types of coated pipes.

3PE vs. Bitumen Coated Pipes

While bitumen-coated pipes offer some degree of protection, they do not provide the same level of corrosion resistance and durability as 3PE coatings. The latter is better suited for long-term underground applications.

3PE vs. FBE Coated Pipes

Fusion-bonded epoxy (FBE) coated pipes are another option; however, they can be more brittle and susceptible to damage during installation. The flexibility and toughness of 3PE coatings make them a superior choice for many underground projects.

Best Practices for Installation and Maintenance of 3PE Coated Steel Pipes

To maximize the benefits of 3PE coated steel pipes, following best practices during installation and maintenance is essential.

1. Proper Handling and Storage

During transportation and storage, it’s crucial to protect the pipes from physical damage. Using appropriate lifting techniques and storing them on soft surfaces can help maintain the integrity of the coating.

2. Installation Techniques

Ensuring that the installation site is prepared properly can prevent damage to the pipes. Use the appropriate bedding material and avoid excessive force during installation.

3. Regular Inspections

Conducting routine inspections can help identify potential issues early on. This proactive approach ensures that any wear or damage is addressed before it leads to significant problems.

FAQs About 3PE Coated Steel Pipes

1. What is the lifespan of 3PE coated steel pipes?

3PE coated steel pipes typically have a lifespan of over 50 years, depending on environmental conditions and maintenance practices.

2. Are 3PE coated steel pipes suitable for all soil types?

Yes, they perform well in various soil types, including corrosive soils, due to their excellent protective coating.

3. Can 3PE coated pipes be used for high-pressure applications?

Absolutely, 3PE coated steel pipes are engineered to withstand high pressure, making them suitable for a wide range of applications.

4. What temperature range can 3PE coated pipes handle?

They can typically handle temperatures ranging from -40°C to +80°C, making them versatile for various climates.

5. How do I ensure the quality of 3PE coated pipes?

Choosing reputable suppliers and conducting inspections during manufacturing can help ensure the quality of the pipes.

Conclusion: The Smart Choice for Underground Projects

Opting for **3PE coated steel pipes** in your underground projects is a decision that pays off in terms of durability, cost-effectiveness, and environmental sustainability. Their superior corrosion resistance and ease of installation make them an ideal solution for various applications in the construction industry. By investing in these pipes, you ensure that your infrastructure remains robust and reliable for decades to come. Whether you're working on water management, oil and gas transportation, or HVAC systems, 3PE coated steel pipes are the smart choice to keep your project on the cutting edge.

Blog

Top Reasons to Opt for 3PE Coated Steel Pipes in Your Underground Projects

Top Reasons to Opt for 3PE Coated Steel Pipes in Your Underground Projects

Introduction to 3PE Coated Steel Pipes

In the construction industry, selecting the right materials is crucial for ensuring durability, safety, and cost-effectiveness. When it comes to underground projects, **3PE (Triple Layer Polyethylene) coated steel pipes** stand out as an excellent choice. This innovative solution not