Exploring the Versatile Applications of Stainless Steel Spectacle Blind Flanges in Construction

2025-07-03

Exploring the Versatile Applications of Stainless Steel Spectacle Blind Flanges in Construction

Table of Contents

- 1. Introduction to Stainless Steel Spectacle Blind Flanges

- 2. What Are Spectacle Blind Flanges?

- 3. Significance of Spectacle Blind Flanges in Construction

- 4. Common Applications of Stainless Steel Spectacle Blind Flanges

- 4.1. Piping Systems

- 4.2. Maintenance and Repairs

- 4.3. Shutdowns and Isolation

- 4.4. Safety Precautions

- 5. Benefits of Using Stainless Steel Spectacle Blind Flanges

- 6. Considerations for Selecting Spectacle Blind Flanges

- 7. Installation Techniques for Spectacle Blind Flanges

- 8. Maintenance Practices for Stainless Steel Spectacle Blind Flanges

- 9. Conclusion

- 10. FAQs

1. Introduction to Stainless Steel Spectacle Blind Flanges

In the world of construction, particularly within piping systems, the importance of reliable components cannot be overstated. **Stainless steel spectacle blind flanges** are crucial in ensuring the integrity and efficiency of these systems. By design, they serve to temporarily block off a section of piping, offering a solution that is both practical and essential in various scenarios.

2. What Are Spectacle Blind Flanges?

**Spectacle blind flanges**, often referred to simply as "spectacle blinds," are specialized flange designs used primarily in piping systems. They come in a distinct shape that resembles a pair of spectacles, where one side is a solid disc (the blind) and the other is an open ring (the spacer). This unique construction allows for a straightforward installation process, enabling quick isolation of sections of a piping system without the need for extensive disassembly.

3. Significance of Spectacle Blind Flanges in Construction

In construction, particularly in industries such as oil and gas, water treatment, and chemical processing, the role of spectacle blind flanges is significant. They facilitate efficient maintenance, allow for easy isolation of sections during repairs, and enhance safety by preventing flow in certain parts of the system. Their versatility makes them a preferred choice for engineers and architects.

4. Common Applications of Stainless Steel Spectacle Blind Flanges

Understanding where and how stainless steel spectacle blind flanges are applied can provide valuable insights into their importance in construction.

4.1. Piping Systems

The primary application of spectacle blind flanges is within **piping systems**. They are commonly used to isolate sections of pipelines during maintenance or upgrades. This isolation ensures that work can be carried out safely without disrupting the entire system. In scenarios where maintenance is routine, having these flanges in place can significantly reduce downtime and improve operational efficiency.

4.2. Maintenance and Repairs

**Maintenance and repairs** in large piping systems often require isolating sections to prevent leaks or hazardous spills. Spectacle blind flanges allow for a quick and efficient method to block off sections while other parts of the system remain operational. This capability is especially beneficial in industries where continuous operation is critical.

4.3. Shutdowns and Isolation

During planned shutdowns, it is essential to isolate certain parts of the system to ensure safe and effective maintenance. Spectacle blind flanges play a crucial role in these scenarios, providing a reliable means to isolate sections without extensive modifications. Their design simplifies the process, allowing for faster execution of the shutdown procedures.

4.4. Safety Precautions

Safety is paramount in construction, especially when dealing with high-pressure systems. Spectacle blind flanges contribute to safety precautions by securely blocking flow and preventing accidental leaks. Their robust design ensures that even under high pressure, they maintain integrity, thereby safeguarding workers and equipment.

5. Benefits of Using Stainless Steel Spectacle Blind Flanges

Utilizing **stainless steel** for spectacle blind flanges offers several advantages that enhance their performance and durability in construction applications.

1. **Corrosion Resistance:** Stainless steel is inherently resistant to corrosion, making these flanges suitable for various environments, including those with high moisture or chemical exposure.

2. **Strength and Durability:** Stainless steel provides excellent mechanical strength, ensuring that the flanges can withstand high pressure and temperature conditions without failure.

3. **Ease of Use:** The design of spectacle blind flanges simplifies installation and removal, saving time and reducing labor costs during maintenance.

4. **Versatility:** These flanges can be used in a wide range of applications across industries, making them a versatile choice for engineers and contractors.

5. **Cost-Effectiveness:** While the initial cost of stainless steel may be higher than other materials, its long-term durability and low maintenance requirements often lead to lower overall costs.

6. Considerations for Selecting Spectacle Blind Flanges

When selecting stainless steel spectacle blind flanges for construction projects, certain factors should be considered to ensure optimal performance:

1. **Material Grade:** Different grades of stainless steel offer varying levels of corrosion resistance and strength. Choosing the right grade for the specific application is crucial.

2. **Size and Diameter:** The size of the flange must match the corresponding piping system to ensure a secure fit and proper flow control.

3. **Pressure Rating:** Understanding the pressure requirements of the system will help determine the appropriate flanges to use, as they come with different pressure ratings.

4. **Standards and Certifications:** Ensure that the chosen flanges meet industry standards and certifications, which can affect performance, safety, and regulatory compliance.

7. Installation Techniques for Spectacle Blind Flanges

Proper installation of stainless steel spectacle blind flanges is essential for ensuring their effectiveness and safety. Here are some key techniques:

1. **Preparation:** Before installation, clean the surfaces of the flange and the pipe to remove any debris or contaminants.

2. **Alignment:** Carefully align the flange with the pipe to ensure that it is positioned correctly and fits snugly to prevent leaks.

3. **Bolting:** Use appropriate bolts and gaskets to secure the flange to the pipe. Ensure that the bolts are tightened in a crisscross pattern to distribute the pressure evenly.

4. **Inspection:** After installation, inspect the assembly for any signs of misalignment or potential leaks. Conduct pressure tests if necessary to verify the integrity of the connection.

8. Maintenance Practices for Stainless Steel Spectacle Blind Flanges

Routine maintenance of stainless steel spectacle blind flanges is necessary to ensure longevity and optimal performance. Here are some best practices:

1. **Regular Inspections:** Schedule regular inspections to check for signs of wear, corrosion, or leaks. Early detection can prevent costly repairs.

2. **Cleaning:** Keep the flanges clean, especially in corrosive environments. Use appropriate cleaning solutions to remove any buildup that may affect performance.

3. **Lubrication of Bolts:** Periodically lubricate the bolts to prevent seizing, which can complicate future maintenance.

4. **Monitoring Pressure:** Continuously monitor the pressure within the system to ensure it remains within the specified limits, as excessive pressure can strain the flanges.

9. Conclusion

Stainless steel spectacle blind flanges serve as essential components in construction, particularly in piping systems. Their unique design, combined with the durability and corrosion resistance of stainless steel, makes them invaluable for maintenance, repairs, and safety. By understanding their applications and best practices, construction professionals can optimize their use, ensuring efficient and safe operations.

10. FAQs

What is a spectacle blind flange?

A spectacle blind flange is a specialized piping component designed to isolate sections of a pipeline. It consists of a solid disc and an open ring, allowing for straightforward installation and maintenance.

Why choose stainless steel for spectacle blind flanges?

Stainless steel offers superior corrosion resistance and strength, making it ideal for use in various environments, particularly where moisture and chemicals are present.

How do I install a spectacle blind flange?

To install a spectacle blind flange, prepare the surfaces, align it with the pipe, secure it with bolts, and inspect for leaks.

What maintenance is required for spectacle blind flanges?

Regular inspections, cleaning, and monitoring of pressure are necessary to ensure the longevity and performance of spectacle blind flanges.

Can spectacle blind flanges be used in high-pressure systems?

Yes, spectacle blind flanges can be designed to withstand high-pressure systems, but it is crucial to select the appropriate size and pressure rating for your specific application.

Blog

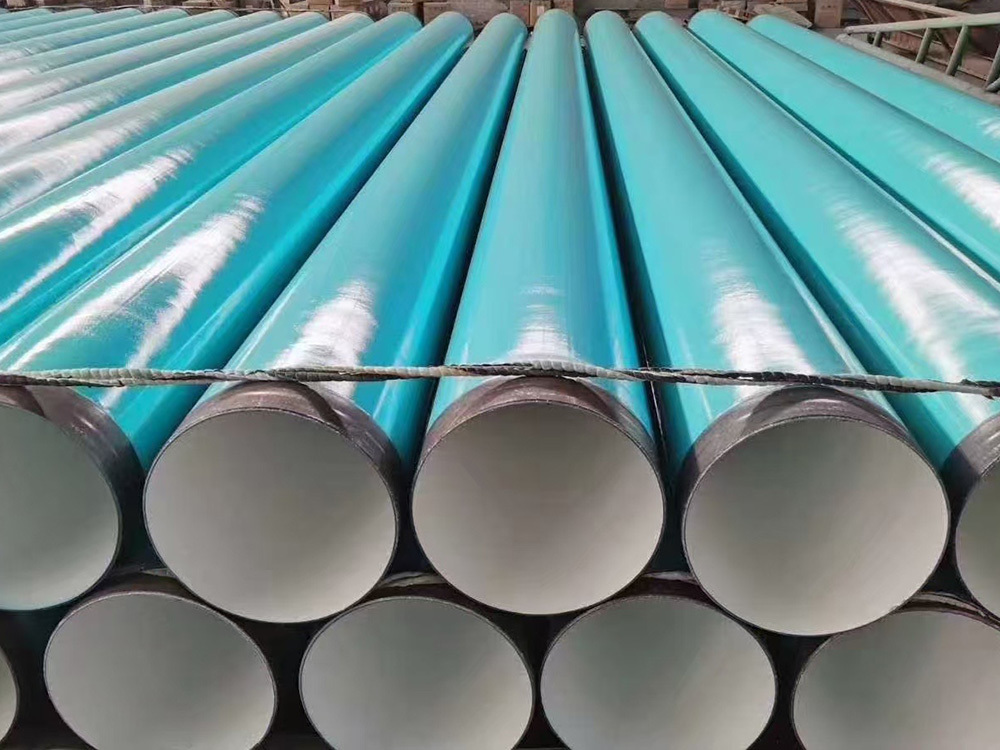

Exploring the Benefits of 3PE Anti-Corrosion Pipeline for Offshore Applications

In the realm of industrial equipment and components, particularly in the pipeline sector, the integrity and durability of pipelines are paramount, especially for offshore applications. One of the most significant advancements in pipeline technology is the development of the 3PE (three-layer polyethylene) anti-corrosion pipeline, which provides an effective solution for combating corrosion in chall